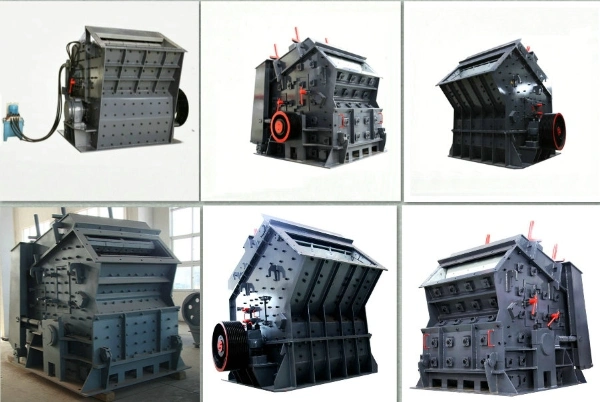

The PFW series Euro-style impact crushers are new high-efficiency hydraulic control impact crushers

developed on the basis of international advanced technology for impact crushers, mainly to ease main-

tenance operation of impact crushers, improve the service life of wearing parts and the equipment

performance, also reduce the processing cost for crushing materials. And it has innovatively designed

the rotors and impact frames, introduced a hydraulic system for adjustment control and top opening

operation, and simultaneously developed coarse and intermediate crushing models according to

users' demands to satisfy different job requirements.

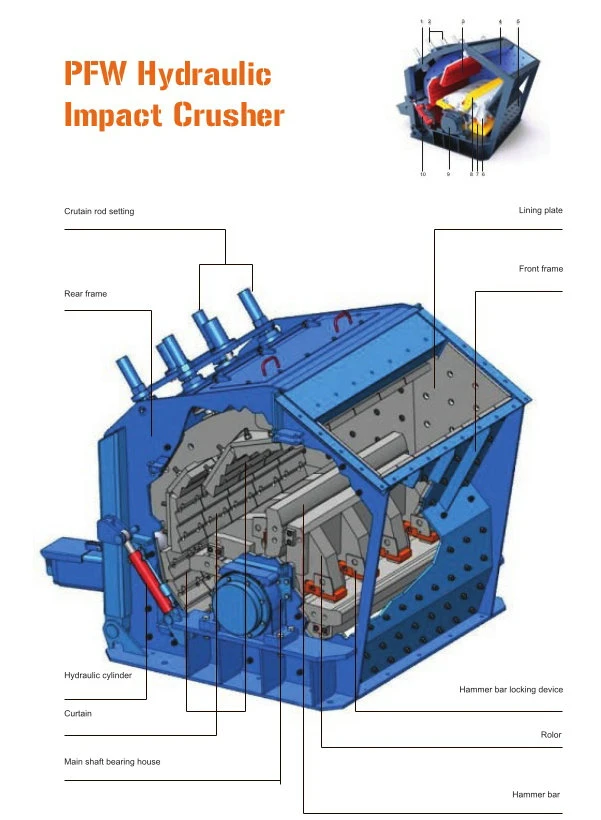

Working principle of PFW series impact crusher

When the pfw impact crusher for sale works, the motor drives the rotor rotate with high speed,on the rotor where installed the hammers. When the materials are feeded in to the machine,they are crushed due to the high speed impact of the hammer and then are thrown to the impact plates on the secondary rotor for secondary crush. Then the materials will be shot back to the hammers again for the third crush. This process repeats until the materials are crushed into the required size and discharged from ourlet.

Applications of PFW series impact crusher

PFW impact crusher, construction impact crusher machine is mostly used as secondary crusher and it well fits for crushing numerous medium and soft mineral &rock materials, such as limestone, feldspar, calcite, talc, barite, clay, tombar thite, kaolin, gypsum, and graphite, construction waste etc...

Features of PFW series impact crusher

Advantages of PFW series impact crusher

1. Hydraulic operation system, more convenient maintenance

2. More special design rotor, higher production efficiency

3. The optimal design of the cavity type can ensure better-shape aggregate

4. Two models are configured to achieve wider application

We provide different types crushers to meet your requirements

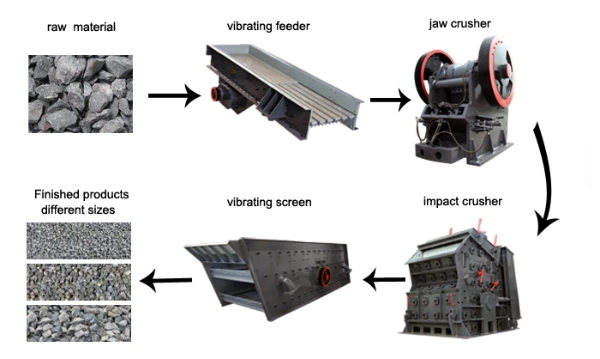

We also provide complete stone crushing line

Technical Parameters of PFW series impact crusher

Table 1: for crusher with three crushing chambers:

Model | Feed opening (mm) | Max. Feed size (mm) | capacity (t/h) | Power (kW) | weight (t) | Overall dimension (mm) |

PFW1214III | 570×1430 | 250 | 90-170 | 132(175) | 16 | 2550×2310×2100 |

PFW1315III | 625×1530 | 300 | 180-270 | 200(270) | 20 | 2960×2570×2380 |

PFW1318III | 625×1830 | 300 | 220-300 | 250(350) | 23 | 2960×2870×2380 |

PFW1415III | 800×1530 | 350 | 280-350 | 250(350) | 22.5 | 3120x2650x2660 |

Table 2: for crusher with two crushing chambers

Model | Feed opening (mm) | Max. Feed size (mm) | capacity (t/h) | Power (kW) | weight (t) | Overall dimension (mm) |

PFW1214II | 1100x1430 | 500 | 130-200 | 132(175) | 18.5 | 2400x2310x2550 |

PFW1315II | 1200x1530 | 600 | 180-320 | 200(270) | 21.5 | 2700x2570x2800 |

PFW1318II | 1200x1830 | 700 | 240-400 | 250(350) | 25.5 | 2700x2870x2800 |

PFW1415II | 1300x1530 | 700 | 300-480 | 250(350) | 25 | 2900x2700x3000 |

Packing&Delivery

Ways of Packing |

1.Sand blasting, coat with high quality paint; |

Shipping |

1."small parts are wooden box package" |

Company Services

Pre-Sale Service:

1) Inquiry and consulting support.

2) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you.

3) View our Factory. Field trips to sell products.

After-Sale Service:

1) After acceptance of the equipment, we will draft the construction program and detailed process, and complete the export process.

2) After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.

FAQ

Q1. How long is the warranty of your equipments? Does your company supply the spare parts?

The warranty period of crusher equipments is 12 months. Yes, we supply the spare parts for you at lowest cost and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Q2. What Information should customers give us? So that we can be able to provide you suitable solution and equipments.

1. What's the capacity you prefer? ( such as 150TPH etc )

2. What is the raw material you want to process? ( such as andesite, basalt, etc )

3. What is the input size of your raw material?

4. What's the final product size do you want?

Q3. Can you test our samples? Do you provide beneficiation flow chart?

Yes. You can send your samples to us for test and analysis. Our experienced engineers are specialized in designing process flow for various ores beneficiation, including iron ore, tin ore, copper ore, gold ore, lead zinc ore, manganese ore, etc.

Q4. If I need the complete crushing plant can you help us to build it?

Yes, we can help you combine a complete crushing line and give you related professional advices as long as you need. We had already build many mining projects in China & Overseas.

If you want to get more details, pls feel free to contact us.

Cathy Chen

Marketing Director

Shanghai Super-Above Industry Holdings Co.,Ltd.

above-power.en.made-in-china.com

above-power.en.made-in-china.com

http://above-power.en.made-in-china.com

http://super-above.en.made-in-china.com

Address:A area,303,Road Daye gong,Shanghai,China

Call:+86-13939060840