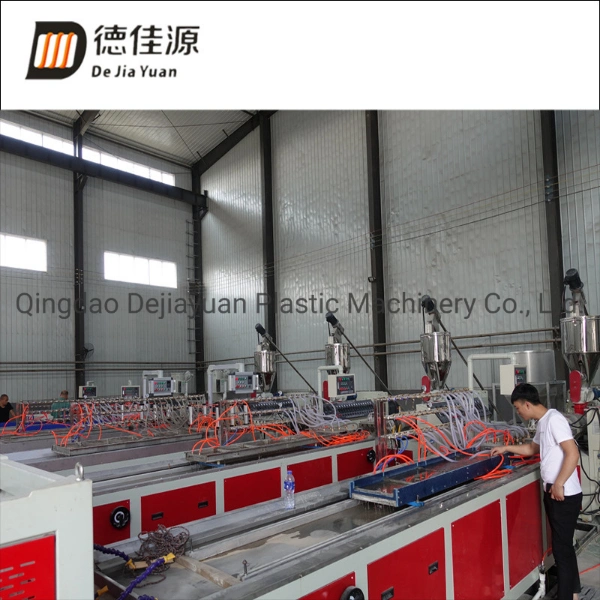

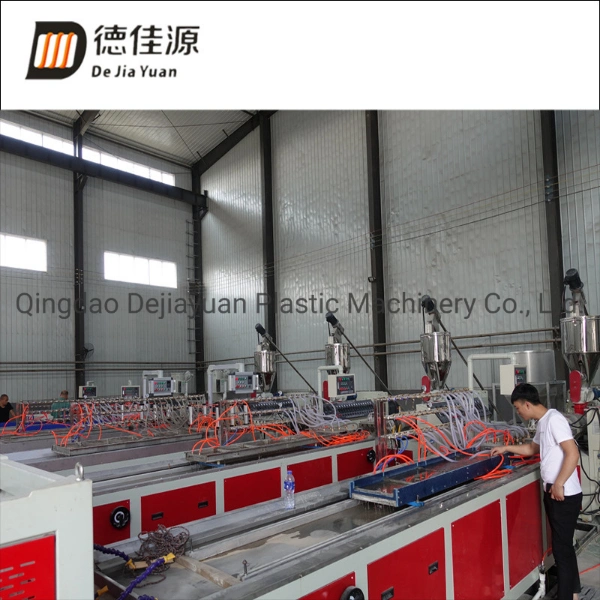

PVC Wood Plastic Foam Board Production Line (SJSZ65)

PVC Wood Plastic Foam Board Production Line is a kind of eco-friendly equipment successfully developed by our company after the adoption of the internationally-advanced technology of wood-plastic board production equipment, combined with our own experience.

This device is characterized by high automation, wide speed range, high precision temperature control, fast production speed, and easy operation and reliability.

The host is a two-cone extruder of SJSZ series with advanced design, large extrusion capacity, and good plasticizing effect, and the auxiliary machine consists of vacuum formizing table, traction machine, cutting machine, and unloading rack.

The crawler tractor, adopted with precision gear motor and inverter, is featured by reasonable structure, large and stable traction.

The cutting machine is reliable and accurate with high precision of cutting.

The wood-plastic product, incorporating the advantages of wood and plastics, is distinguished by resistance to corrosion, moisture, insects, high dimensional stability, and non-cracking feature, and high hardness than pure plastics, and similar to wood in workability and able to be cut, painted, bonded, and fixed by nails or bolts.

Mainly used in wall boards, sidings, decking panels, pallets for packing and logistics, construction timber, storage racks, decorative borders, fences, stair handrails and so on. It is promising and long-lasting.

Main Technical Parameters:

PVC Wood Plastic Foam Board Production Line is a kind of eco-friendly equipment successfully developed by our company after the adoption of the internationally-advanced technology of wood-plastic board production equipment, combined with our own experience.

This device is characterized by high automation, wide speed range, high precision temperature control, fast production speed, and easy operation and reliability.

The host is a two-cone extruder of SJSZ series with advanced design, large extrusion capacity, and good plasticizing effect, and the auxiliary machine consists of vacuum formizing table, traction machine, cutting machine, and unloading rack.

The crawler tractor, adopted with precision gear motor and inverter, is featured by reasonable structure, large and stable traction.

The cutting machine is reliable and accurate with high precision of cutting.

The wood-plastic product, incorporating the advantages of wood and plastics, is distinguished by resistance to corrosion, moisture, insects, high dimensional stability, and non-cracking feature, and high hardness than pure plastics, and similar to wood in workability and able to be cut, painted, bonded, and fixed by nails or bolts.

Mainly used in wall boards, sidings, decking panels, pallets for packing and logistics, construction timber, storage racks, decorative borders, fences, stair handrails and so on. It is promising and long-lasting.

Main Technical Parameters:

Production Line Type | Extruder Model | Maximum Product Length (mm) | Main Motor Power (KW) | Production Capacity (kg/h) |

JJ-SJSZ65/132 | SJSZ65/132 | 600 | 37 | 120-180 |

JJ-SJSZ80/156 | SJSZ80/156 | 800 | 55 | 180-220 |

JJ-SJSZ92/188 | SJSZ92/188 | 1000 | 110 | 220-300 |